Link to PDF

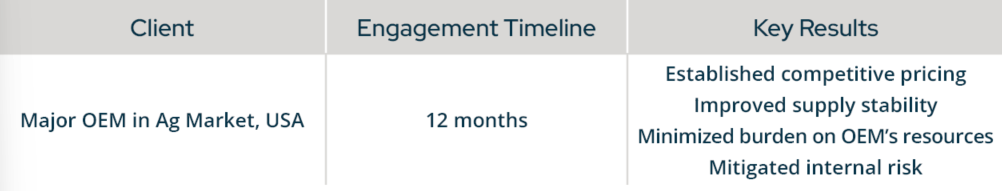

Major OEM in Ag Market

Competitive Cost with Long-Term Supply Stability - Drive Good Outcomes

Executive Summary:

The Integration Group (TIG) uncovered significant time and cost savings for this OEM through optimized supplier management, procurement and fulfillment strategies — all within a 12-month start-to-implementation timeline.

The Challenge:

A Major OEM was experiencing issues related to the management of slow-turn parts across their various divisions, specifically in their JDPS operations. These included:

• Fluctuating and unpredictable demand for these parts made forecasting and inventory management highly complex and resource intensive.

• The low-volume parts often led to higher unit costs due to a lack of economies of scale, coupled with potential storage and obsolescence expenses.

• Suppliers often imposed high minimum order quantities, forcing this OEM to purchase more parts than immediately needed — tying up capital and increasing inventory holding costs.

• JDPS lacked the internal resources or specialized expertise to effectively manage manufacturing suppliers and extract maximum value.

Our Solution:

To achieve favorable pricing for slow-turn parts and assure a consistent and uninterrupted supply over the long term, TIG developed a solution that would mitigate risks associated with supply chain disruptions while reducing costs to this OEM.

TIG proactively managed the entire supply chain for these slow-turn parts — anticipating potential issues, optimizing inventory levels, and implementing strategies to ensure smooth operations rather than reacting to problems as they arose. This included managing supplier relationships, negotiating terms and ensuring quality control.

Key Outcomes:

• Uncovered Cost Savings: Achieved competitive pricing for slow-turn parts through supplier negotiation, volume aggregation and optimized procurement

and fulfillment strategies.

• Reduced Downtime with a Reliable Supply: Reduced lead times, minimized stock-outs and improved on-time delivery performance for critical slow-turn

parts — boosting customer satisfaction.

• Minimized Internal Resource Burden: Freed up the OEM's internal team resources by outsourcing the management of complex parts.

• Proactively Mitigated Risk: Helped identify and mitigate potential risks such as supplier financial instability, geopolitical disruptions and material shortages

to safeguard the OEM's operations.

Incremental Value Delivered:

• Kitting and Complex Assembly: Provided pre-assembled parts and kits — reducing labor time and potential errors, streamlining processes and ensuring customer satisfaction.

• Supplier Resourcing Help: Identified new or alternative suppliers within the TIG managed supply chain for critical part sourcing.

Why it Matters

This case study demonstrates how TIG’s supply chain solutions provide our partners with greater flexibility, process optimization, risk diversification and cost savings through favorable pricing.

Ready to Optimize Your Supply Chain?

The Integration Group is ready to help.